When I started soldering everything was big and had leads that went through holes in the board. You inserted the leads, bent them over to hold the component, flipped the board over, soldered everything, and trimmed off the excess leads.

Now I’m soldering things down to 0402 SMDs (1/4 the size of the smallest component in the picture) using a needle point soldering tip and a microscope.

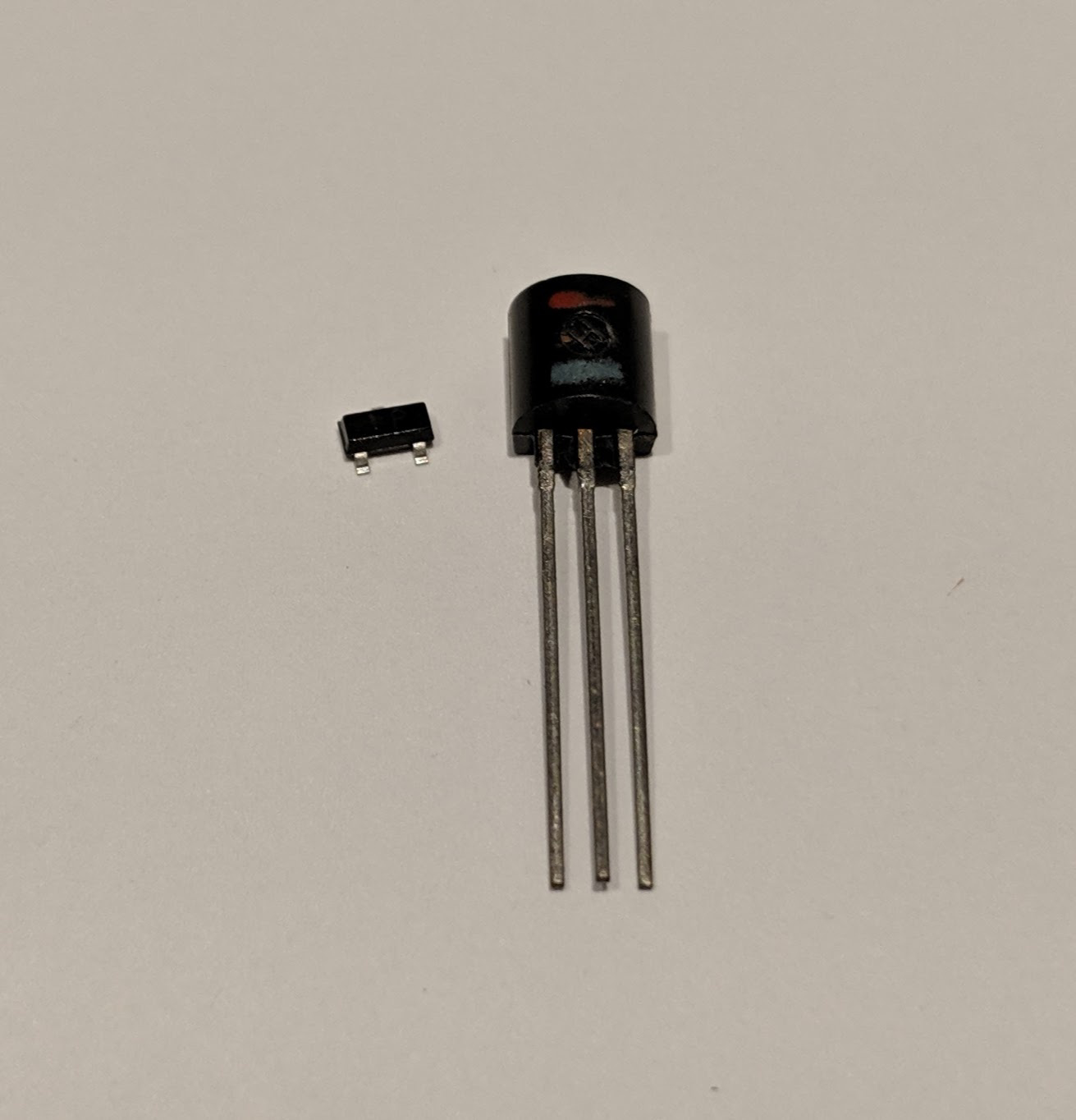

A pair of 2N2222 transistors, one SOT23 and one TO-92.

Just commenting to say that I love the fact that this discussion/community randomly popped up in my feed. SMD soldering gives me the heebie-jeebies

Welcome. It’s more of a challenge than soldering THT, that’s for sure, but it can be done even with basic equipment. I’m going to Walmart tomorrow to buy a $10 soldering iron and I’m going to remake the SMD soldering videos on my YouTube channel using that $10 iron to show that it can be done. No one should be afraid of soldering SMDs.