When I started soldering everything was big and had leads that went through holes in the board. You inserted the leads, bent them over to hold the component, flipped the board over, soldered everything, and trimmed off the excess leads.

Now I’m soldering things down to 0402 SMDs (1/4 the size of the smallest component in the picture) using a needle point soldering tip and a microscope.

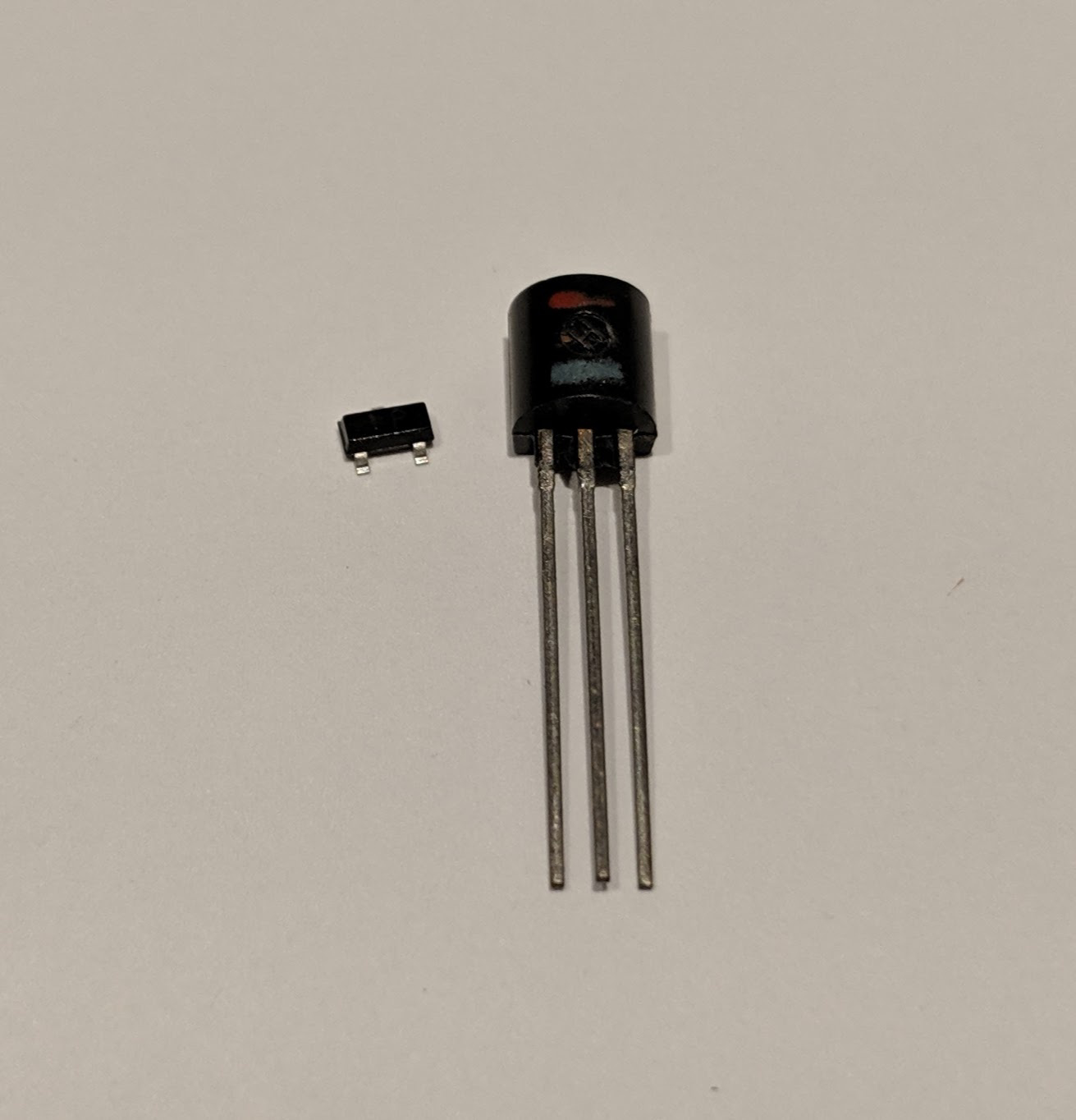

A pair of 2N2222 transistors, one SOT23 and one TO-92.

Ive been having my fair share of troubles woth 0402s at work after I ripped all of the smd test point pads off woth oscilloscope probes. I ended up with a ton of wires kapton taped to the board and poked into a 0402 joint, and miscellaneous circuits deadbugged and built up with point to point wires. My favorite was bending tbe legs on a sot-6 up to hold a resistor and cap, and the top half the the voltage divider was floating in the air over the board

Adventures in soldering. Are you prototyping or are these production systems. I have one that I built a while ago that I’m not proud of but it works.

Hehehe. When I was looking for that one I found this monstrocity.

I had run out of adapter boards for the SOIC chip. I have a new stock of them now.