5

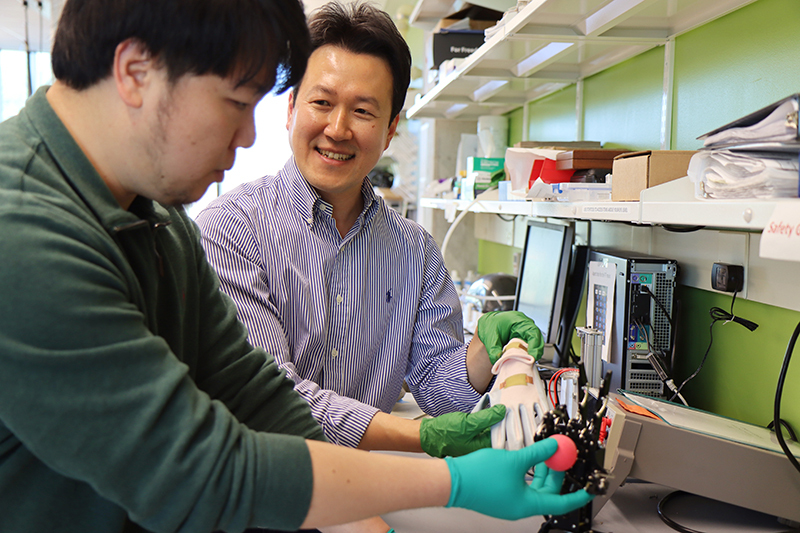

A patent-pending method developed by Purdue University researchers brings the public one step closer to clothes with wearable electronics that don’t affect the wearer’s comfort. The method also simplifies the manufacturing process and boosts sensing capability. Wearable electronics that monitor bioinformation like blood pressure, body temperature and respiratory patterns have become prominent in research. Traditional wearable devices such as health-monitoring systems, however, are hard and inflexible, which makes them difficult to wear for extended periods of time. Furthermore, fabricating wearable sensors onto clothing creates different sets of problems, said Sunghwan Lee, assistant professor of engineering technology in the Purdue Polytechnic Institute. Traditional sensors eliminate fabric breathability, or the circulation of air from the inside to the outside. Breathability allows vapor moisture to diffuse, which prevents people from overheating and keeps them comfortable. “This is significant especially when sensors have military or medical assistive rehabilitation applications,” Lee said. “People need to wear these electronics for long periods of time. It isn’t convenient to replace them in the middle of a rehab session or military exercise. “These limitations are caused by the traditional method to fabricate sensors on clothing. It relies on either brittle and inflexible inorganic materials, which lack longer-cycle stability, or liquid-phase processing, which is unable to create conformal coating on fabrics and hence makes it difficult to secure the required breathability.” Lee and his team have used a technique called oxidative chemical vapor deposition, or oCVD, to form highly conducting and mechanically flexible polymer films conformally coated on every thread of fabric. It controls the thickness of the polymer layer, called PEDOT, while maintaining the fabric’s breathability and flexibility. Lee and his team demonstrated the method by directly depositing and patterning the PEDOT layer on commercially available disposable gloves and masks to create blood pressure- and respiratory rate-monitoring sensors. The team confirmed the mechanical flexibility of the conformally vapor-printed PEDOT layer through cyclic bending tests on fabric samples coated with various thicknesses of the films at different temperatures.

www.purdue.eduPatent-pending technique creates sensors that demonstrate high flexibility and strain sensitivity but don’t affect breathability.

You must log in or # to comment.